Yonga ixesha kwaye ugcine iindleko zenkcitho ziphantsi xa usenza uhlalutyo lobungakanani okanye ugcina imathiriyeli.Iibhotile zethu zesampulu zeglasi ye-silane zaphathwa ngendlela ye-silane yokubeka umphunga.Unyango lwe-passivation yoMphezulu olufana ne-silanization kunye ne-sililicification zibalulekile ukugcina ingqibelelo yezinto ezithile okanye izicatshulwa ezigcinwe kwizikhongozeli zeglasi.Ukuguqulwa komphezulu kunokunciphisa iisayithi ezisebenzayo kwindawo yeglasi ye-borosilicate.

Inkqubo yonyango oluphezulu lwezixhobo zetsimbi okanye ezingezizo ezentsimbi kunye ne-organosilane enamanzi njengeyona nto iphambili.I-Silanization ineenzuzo ezilandelayo kwi-phosphating eqhelekileyo: akukho ion yensimbi eyingozi enzima, akukho phosphorus, kwaye akukho mfuneko yokufudumeza.Inkqubo yonyango ye-silane ayivelisi intlenga, ixesha lonyango lifutshane, kwaye ulawulo lulula.Amanyathelo okucubungula angaphantsi, inkqubo yokulungiswa kwetafile inokushiywa, kwaye i-tank liquid ingaphinda isetyenziswe.Ukuphucula ngokufanelekileyo ukunamathela kwepeyinti kwi-substrate.I-Collinear processing ye-iron sheet, i-galvanized sheet, i-aluminium sheet kunye nezinye i-substrates.

(1) Unyango lwe-Silane aluqulathanga isinyithi esiyingozi esinzima njenge-zinc kunye ne-nickel kunye nezinye izinto eziyingozi.I-nickel ibonakaliswe ukuba iyingozi kumzimba womntu.I-World Health Organization (WHO) ichaza ukuba i-nickel kufuneka ikhutshwe kwi-zero emva kwe-2016, ifuna ukuba i-nickel ayifanele ifakwe kwi-phosphating wastewater, i-phosphating vapor kunye ne-phosphating grinding dust.

(2) Unyango lweSilane luvelisa kuphela inani elincinci kakhulu le-silane slag, kwaye iindleko zonyango ze-slag ziphantsi kakhulu.

I-Phosphating slag liqabane elingenakuphepheka lokusabela kwendabuko ye-phosphating.Ngokomzekelo, umgca wokuvelisa imoto usebenzisa iiplati ezibandayo ezibandayo ziya kuvelisa malunga ne-600g ye-phosphating slag kunye ne-50% yomswakama womswakama kwi-processing ye-1 imoto (elinganiswe ngu-100m2), kunye nomgca wokuvelisa iimoto ze-100,000 ziya kuvelisa i-60t ye-phosphating slag ngonyaka.

(3) Akukho mkhuthazi we-nitrite ofunekayo, ngaloo ndlela ugwema umonakalo we-nitrite kunye neemveliso zayo zokubola kumzimba womntu.

(4) Ukusetyenziswa kwemveliso kuphantsi, kuphela i-5% ~ 10% ye-phosphating.

(5) Akukho nkqubo efana nokulungiswa kwetafile kunye nokupasa kunyango lwe-silane.Amanyathelo okuvelisa amancinci kunye nexesha elifutshane lokucubungula luncedo ekuphuculeni umthamo wemveliso yefektri, ukunciphisa umgca omtsha wemveliso, kunye nokugcina utyalo-mali lwezixhobo kunye nommandla womgangatho.

(6) Ubushushu begumbi buyenzeka, kwaye konga amandla.Isisombululo setanki yeSilane ayifuni kufudunyezwa, kwaye iphosphating yesintu ifuna ngokubanzi i35 ~ 55℃.

(7) Akukho ngquzulwano kunye nenkqubo ekhoyo yezixhobo, kwaye akukho kuguqulwa kwesixhobo kunokutshintshwa ngokuthe ngqo kwi-phosphating;Iyahambelana nenkqubo yokuqala yokwaleka kwaye inokudityaniswa nazo zonke iintlobo zepeyinti kunye nomgubo osetyenziswayo.

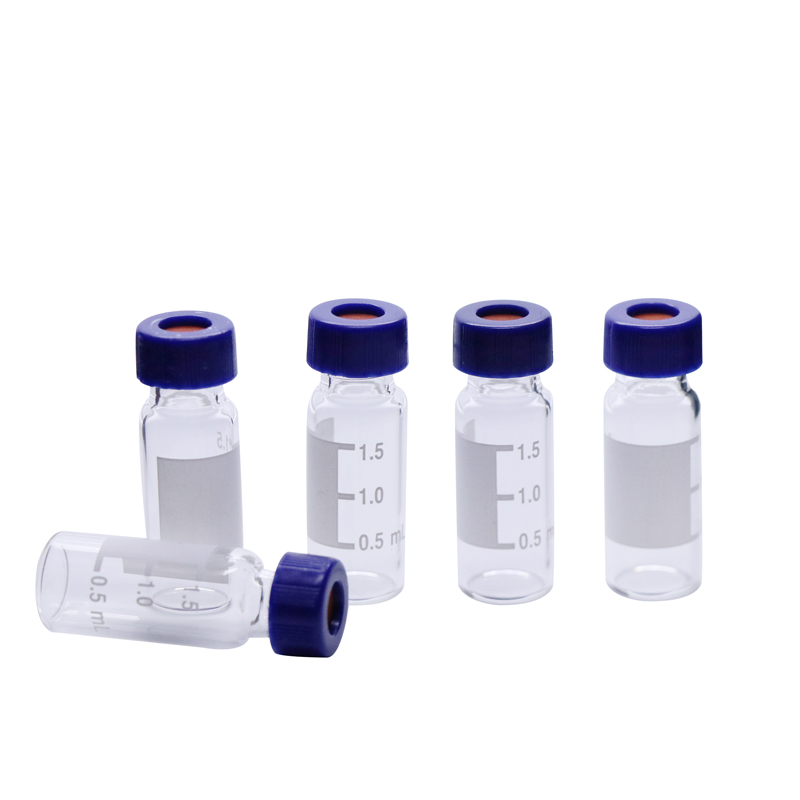

Iglasi yeBorosilicate yimathiriyeli edumileyo yeengqayi zeHPLC kuba ineepropathi ezigqwesileyo zeekhemikhali kunye nokumelana nobushushu.Olu hlobo lweglasi lufanelekile kwizicelo ze-HPLC kuba luyakwazi ukumelana nokushisa okuphezulu kunye nezinyibilikisi ezinamandla ezihlala zisetyenziswa kwi-HPLC.

Xa ukhetha ii-vials ze-HPLC, kubalulekile ukuqwalasela uhlobo lwesampulu ehlalutywayo kunye neemeko apho uhlalutyo luya kwenziwa khona.I-amber borosilicate glass HPLC Vials kunye nokuvulwa kwe-9mm lukhetho oludumileyo kwizicelo ezininzi zebhubhoratri ngenxa yeempawu zabo zokusebenza ezigqwesileyo kunye nokuhambelana noluhlu olubanzi lweesampulu kunye neemeko.

Ukongeza kwi-vial ngokwayo, i-septa iyafuneka kwakhona kuhlalutyo lwe-HPLC.I-septa yintwana encinci, isangqa sesixhobo esingena kwi-vial kwaye sisebenza njengetywina.Ivumela ukuqaliswa kwesampuli kwi-vial kwaye inika umqobo phakathi kwesampuli kunye nesirinji ye-HPLC, ukukhusela ukungcoliswa.Xa ukhetha i-septa yee-vials ze-HPLC, kubalulekile ukuqwalasela uhlobo lwesampulu ehlalutywayo kunye neemeko apho uhlalutyo luya kwenziwa khona.

Ixesha lokuposa: Mar-30-2023